Production Process of Silicone Swimming Cap

- Share

- Issue Time

- Aug 21,2023

Summary

Have you ever wondered how durable silicone swim caps are made? In this article, we will delve into the production process of silicone swimming caps from raw materials to finished products.

Silicone swim caps have become a must-have accessory for both amateur and professional swimmers. Not only are these hats stylish, but they also function to reduce drag and protect your hair from chlorine and other chemicals in the pool. Ever wonder how these stylish and durable hats are made? In this article, we will delve into the fascinating production process of silicone swimming caps from raw material to finished product.

Learn About Silicone Swimming Caps

Silicone swim caps are must-have swimming gear, made of silicone rubber, known for its durability and flexibility. These caps provide a comfortable fit, minimize water resistance to enhance swimmer performance, and protect hair from pool chemicals. They come in a variety of colors and customizable designs, making them a popular choice for both recreational and professional swimmers. Plus, the silicone cap is easy to maintain, suitable for swimmers of all hair lengths, and a reliable accessory for the swimming world.

Manufacturing Steps of Silicone Swimming Cap

Raw Material Procurement: The production process begins with the procurement of high-quality silicone rubber. Manufacturers carefully select silicone compounds that meet specific criteria for elasticity and tear resistance.

Mixing and Coloring: At this stage, the silicone is mixed with the pigment to obtain the desired color. This step ensures that the cap is available in a variety of colors to suit individual preferences.

Forming: Forming is a critical step in the production process. Liquid silicone is poured into the mold, which is usually made of aluminum. These molds are designed to accurately replicate the shape and size of the swim cap.

- Compression Molding: Compression molding is the most commonly used technique. The mold is heated and pressure is applied to ensure that the silicone takes the shape of the mold perfectly.

- Injection Molding: Some manufacturers choose injection molding, where liquid silicone is injected into the mold under high pressure. For complex designs, this method is preferred.

- Vulcanization: Vulcanization is the process of heating molded silicone. This step ensures that the silicone becomes elastic and retains its shape even after prolonged use.

Quality Control: In the production of silicone swimming caps, maintaining quality is of the utmost importance. Manufacturers conduct rigorous testing to check for defects such as tears or inconsistent colors.

Trimming and Finishing: Excess silicone is trimmed and edges are finished to ensure a smooth, comfortable fit for swimmers.

Logo and Design Application: Many swim caps have a logo or design. These can be applied using various techniques including screen printing or embossing.

Final Inspection: Each swim cap undergoes a final inspection before reaching the consumer. This ensures that only the highest quality caps reach the market.

These steps combine science and craftsmanship to create a silicone swim cap that not only looks great but also enhances a swimmer's performance.

In Conclusion

The production process of silicone swimming caps is a fusion of science and technology. It involves precise steps from material selection to molding, vulcanization, and quality control to create products that not only look great but also enhance a swimmer's performance. So the next time you put on a silicone swim cap, you can admire its intricate manufacturing process.

The above has introduced the production process of silicone swimming caps, if you want to know more or want to buy silicone swimming caps, please contact us.

Shengbailong is a professional custom swimming and diving equipment manufacturer. Specializing in the production of silicone swimming caps, swimming goggles, diving masks, snorkels, and other products. The factory is equipped with mold CNC machines, injection molding machines, hydraulic presses, and related equipment for anti-fog and mirror processing. The production cycle is less than 30 days, and the monthly production capacity reaches 300,000 pieces. We are proud to be a reliable partner of some of the world's most recognized brands.

Frequently Asked Questions

Are Silicone Swim Caps Better Than Latex Swim Caps? Silicone caps are often preferred for their durability and comfort. Latex caps are thinner but may have a shorter lifespan.

Can I Customize a Silicone Swim Cap? Yes, many manufacturers offer custom printing options that allow you to add your logo or design.

How to Clean and Maintain a Silicone Swim Cap? Rinse with clean water and air dry after each use. Avoid prolonged exposure to direct sunlight.

Are Silicone Swim Caps Suitable for Long Hair? Yes, the silicone caps are stretchy and can comfortably accommodate a variety of hair lengths.

Do Professional Swimmers Prefer Silicone Swim Caps? Many professional swimmers choose silicone swim caps for their streamlined design and performance benefits.

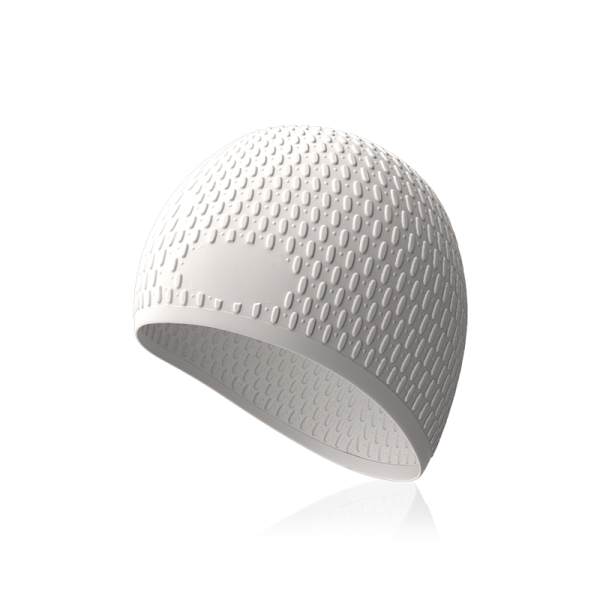

Super-durable Silicone Swimming Cap. Snag-free, helping to protect your hair against chlorine during your swim.

Our long-lasting Bubble Cap features a bubble-textured design which helps achieve a smooth flow through the water.

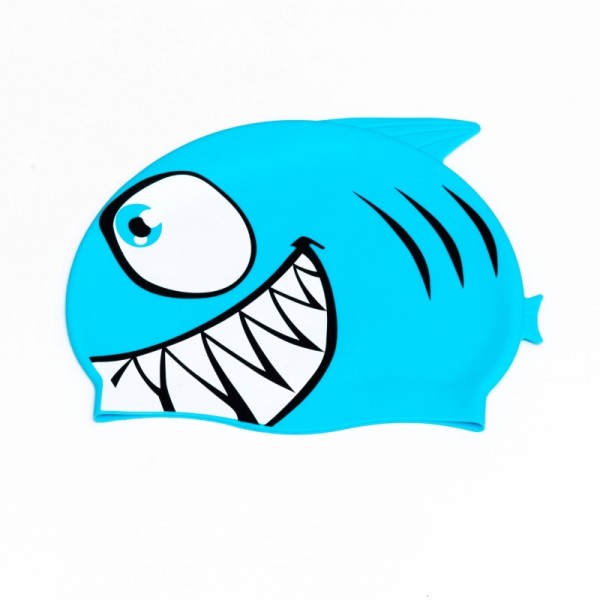

Enjoy the water with fun animal designs. Soft, 100% silicone offers a durable and comfortable fit.

Super-durable Silicone Swimming Cap. Snag-free, helping to protect your hair against chlorine during your swim.